Virtual Test Facilities And Exercises

In the last section of VLab laboratory exercises are included. The exercises are performed in a way that is a reproduction of actual laboratory tests. Particularly, the first one deals with basics such as measurement techniques, the second one with turbo machinery component operation and the third one with operation of an entire engine. The exercises are performed through simulation programs while audio and animation effects have been added in order to simulate the real laboratory environment in all exercises. These effects are changed according to user interaction, so for example engine sound changes according to operating point (% speed).

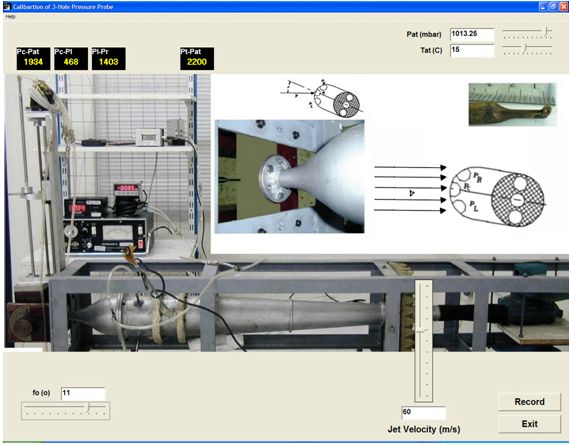

The first exercise is an introduction in calibration methods of 3-hole pressure probes used for fluid pressure and velocity measurements in turbo machinery.

Virtual Exercise: 'Calibration of 3-Hole Probe'

Virtual Exercise: 'Calibration of 3-Hole Probe'

An image of the real test facility, the instruments location and the virtual indicators of the measurement quantities are shown in the main screen of the corresponding exercise simulation program. For the execution of the exercise, the students have to record all measurement quantities for different probe angles after setting a constant jet velocity and then to process them in order to calculate the calibration curves.

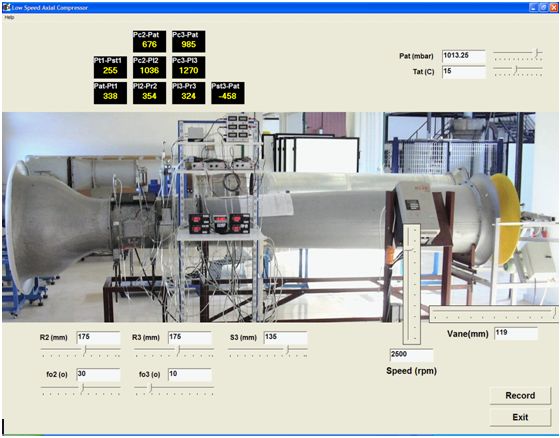

The scope of the second exercise is (a) to determine experimentally the characteristic curve of a single stage axial compressor (b) to measure flow field quantities in the interior of the stage in order to establish the cross-correlation of flow kinematics' elements with the operating point of the stage.

Virtual Exercise: 'Measurement of Characteristic Curve of a Single Stage Axial Compressor'

Virtual Exercise: 'Measurement of Characteristic Curve of a Single Stage Axial Compressor'

The real test facility, in this case, consists of a low speed compressor test ring with a single axial stage installed and a throttling vane for mass flow control. Two 3-hole probes are used, located at rotor and stator exit respectively. A Pitot-Prandl tube is also located at stage inlet. For the execution of the exercise, the student regulates the compressor rotational speed and sets the throttling valve in fully open position. Beginning from this position, starts to close the valve in successive places of smaller opening, giving in this way a smaller amount of mass flow. For each throttling position the student moves the probes in successive radial locations from tip to hub. For each location the student records all the measured quantities and then processes them for calculation of compressor characteristic curve and detailed flow field parameters.

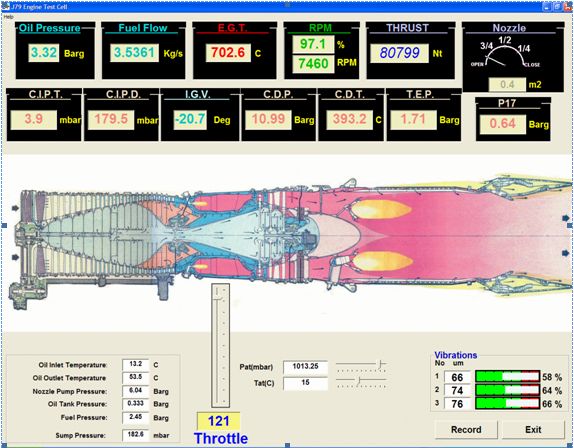

The third exercise is a reproduction of jet engine test cell. The aim is the familiarization of students with jet engine tests, examination and engine management procedures. For this exercise all the measurements taken in a real test cell for the evaluation of the engine's health condition have been simulated.

Virtual Exercise: 'Reproduction of a Jet Engine Test Cell'

Virtual Exercise: 'Reproduction of a Jet Engine Test Cell'

The control of the engine operation is performed through the throttle lever which is simulated with the corresponding slider shown in main screen of the exercise simulation program. The position of the lever determines the values of all indicated measurement quantities.