LTT has developed well validated methods allowing gas turbine engine condition monitoring and fault diagnosis. All these methods are the result of an intense basic research activity for more than 15 years and the participation in several funded research projects.

The developed diagnostic methods are programmed in FORTRAN or VB language and they can be delivered either as executable files or as DLL files that can be embedded into other software systems (e.g. Microsoft Office EXCEL, MATLAB, etc.). Furthermore, all methods can be customized to meet the specific needs and requirements of a user.

Available diagnostic methods are:

- Pattern Recognition

This diagnostic method allows gas turbine engines fault diagnosis using various pattern recognition techniques (Geometrical Pattern Recognition, Statistical Pattern Recognition and Statistical Pattern Recognition with Optimal Directions).

This diagnostic method is a classification method. A given piece of input information is classified into one, among many, predefined classes that represent the engine health condition. This method can be applied on a wide range of diagnostic problems ranging from the detection of sensor malfunctions on gas turbine measurements instrumentation, to the diagnosis of engine component faults.

- Probabilistic Neural Networks (PNN)

This is also a classification method, based on a specific architecture of Artificial Neural Networks (ANN), the Probabilistic Neural Network (PNN). This method performs rather stochastic than deterministic pattern recognition, providing also a measure of confidence of the resulted classification.

The training procedure of the PNN diagnostic method consists of the generation of simulated engine conditions, through the use of an Engine Performance Model (EPM).

This method also applies on a wide range of diagnostic problems ranging from the detection of sensor malfunctions on gas turbine measurements instrumentation, to the diagnosis of engine component faults.

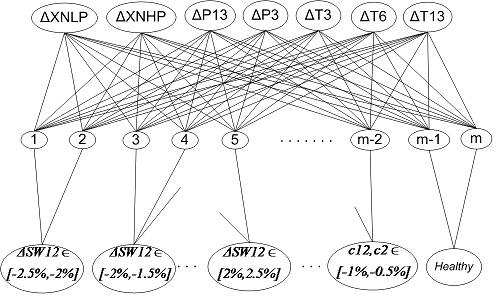

A typical architecture of the PNN diagnostic method is shown below.

- Bayesian Belief Network (BBN)

Bayesian Belief Networks (BBN) is a type of probabilistic expert system that combines Graph Theory with Probability Theory, allowing an efficient handling of stochastic variables and probabilistic propagation.

The BBN diagnostic method, handles all diagnostic parameters of a gas turbine as stochastic parameters. Interrelation among parameters is reproduced by an Engine Performance Model (EPM) of the engine. Once information about the engine is available (e.g. measurements acquired along engine stations), the value of the corresponding parameters is defined, while the value of the remaining (unknown) parameters is propagated.

So far, two configurations of the BBN diagnostic method exist:

- The Static-BBN. In this configuration all diagnostic parameters of a gas turbine under examination, are considered as stochastic parameters with fixed discrete values.

- The Dynamic-BBN. In this configuration all diagnostic parameters of a gas turbine that represent measurable quantities, are considered as stochastic parameters whose values are dynamically adjusted to reflect acquired measurements.

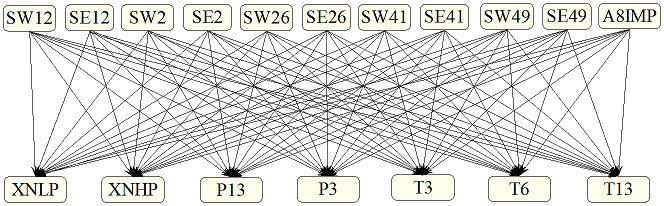

A typical architecture of the BBN diagnostic method is shown below.

- Support Vector Machines (SVM)

SVM is a modern approach in classification methods, according to which examined patterns are classified into classes, separated to each other through hyper-planes in a multidimensional space. These hyper-planes are defined through known patterns, the so-called ‘support vectors’.

In the SVM diagnostic method, classes are potential engine fault situations or possible engine health conditions, while patterns are vectors of available measurements acquired from the engine. The required hyper-planes are defined through simulated engine conditions with the aid of an Engine Performance Model (EPM).

- Dempster-Schafer fusion method (D-S fusion)

This is not a standalone diagnostic method, but a method that merges the results of independently acting diagnostic methods. This method reflects the modern diagnostic approach, according to which, and in order to increase the credibility of diagnostic conclusions, these must be extracted taking into account more than one sources of information.

D-S fusion method is based on the Demster-Schafer theory, on which each variable is given a ‘mass’ reflecting our belief about its value.

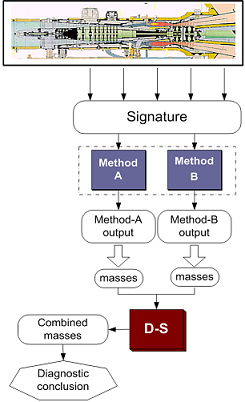

A schematic presentation of the D-S fusion method, applied on two diagnostic methods, is shown in the figure below.

Data obtained from the engine under examination are processed to form a signature of its current condition. The signature is the input information on two, independently acting, methods allowing an estimation of engine health condition each (Method-A and Method-B). The output of these two methods is the diagnostic conclusion of each method which is then transformed into ‘masses’, which are the variables involved in the Dempster-Schafer (D-S) theory. The resulting masses are finally combined, through the use of Dempster’s combination rule, leading to the ‘combined masses’. These ‘combined masses’ are a measure of our belief about the health parameters deviation, given the diagnostic results of both independent methods, from which the final diagnostic conclusions are derived.

- Probabilistic Aggregation Fusion Method

LTT has developed a method that deals with information in probabilistic form. This method utilizes the concept of linear opinion pool in order to combine the conclusions (or decisions) by methods that operate independently in order to derive an improved and more accurate final diagnostic decision. Two configurations of the above method have been deployed so far, namely simple combination and parallel aggregation. This method requires a common probabilistic form from all the employed methods and can be coupled with techniques that transform the available information in the field of probabilities. Also, the selection of weights is critical for the efficiency of the presented method and for that purpose two specific methodologies have been deployed, namely the “pessimistic” and the “optimistic” approaches.

- Fuzzy Logic Fusion Method (FL fusion)

This technique is a two-step information fusion technique allowing the combination of the diagnostic decisions of independent diagnostic methods. The independently acting diagnostic methods provide assessments for the condition of an engine and the final decision results from a combination of these assessments through the framework of probabilistic aggregation and fuzzy classification. It is noted that the fuzzy logic classification fusion method has been implemented with two configurations, one that uses only fuzzy sets and one that uses a complete fuzzy inferencing system.

- Certainty Factors Fusion Method (CF fusion)

This method comprises an ad hoc probabilistic reasoning method for dealing with uncertainty in an effective and easy way. CF constitute a popular alternative to probabilistic-like reasoning for cases where the available data for completion of a diagnostic task do not permit a traditional probabilistic approach. CF attempt to measure the confidence posed upon a certain hypothesis (which in this case is a fault class or a given engine health condition) by an expert (which in this case is an independently acting diagnostic method) given the presence of some evidence (which in this case are the available diagnostic information or measurements). A certainty factor is defined based on two functions, namely MB (measure of belief) and MD (measure of disbelief). The knowledge base of the method is comprised by IF-THEN rules. The described method combines the assessments of independently acting diagnostic methods and provide a final conclusion for more refined and accurate diagnosis.

- Combinatorial Method

This method gives the possibility to identify deviations of performance engine health parameters (say N) from a limited number of performance measured quantities (say M). According to this method, the measurement set is fed to an adaptive diagnostic model and a unique solution (estimated deviations of M parameters out of N) is produced. The procedure is applied for all different possible parameter combinations, namely as many times as the number of all possible combinations of N per M. It is noted that each solution is also checked to be inside predefined limits. In engine deterioration for example, performance health parameters of all components decrease, apart from turbine flow function that can either decrease or increase. If such a solution exceeds these limits then it is not taken into account. Finally the method combines all these solutions from the different combinations in order to produce the most probable one.The diagnostic method described here relies on the existence of an engine performance model, which represents the relation among health parameters and measurements along the engine and can simulate both healthy and faulty operation. The user can employ any engine model of different complexity (and accuracy).

- Deterioration Tracking Method

This method also gives the possibility to identify deviations of performance engine health parameters from a limited number of performance measured quantities. The main difference of this method compared with the combinatorial method lies in that the diagnostic algorithm minimizes a proper cost function for specific engine operating conditions. The minimization of the formulated cost function is accomplished by using the Simplex Downhill Method in multi-dimensions. In this method the checking for the solutions to be inside predefined limits is also performed. In case where there is an excess of these limits a penalty is added to the cost function. The diagnostic method described relies on the existence of an engine performance model, which represents the relation among health parameters and measurements along the engine and can simulate both healthy and faulty operation. The user can employ any engine model of different complexity (and accuracy).